Safety First

Keeping our teams safe is paramount, both ethically and financially. Our team uses a strict process for design and implementation that was developed with personal safety in mind. From pre-install safety planning, to daily job safety assessments during install and commissioning, to a stop work attitude, the safety of our team is forefront in our minds and approach.

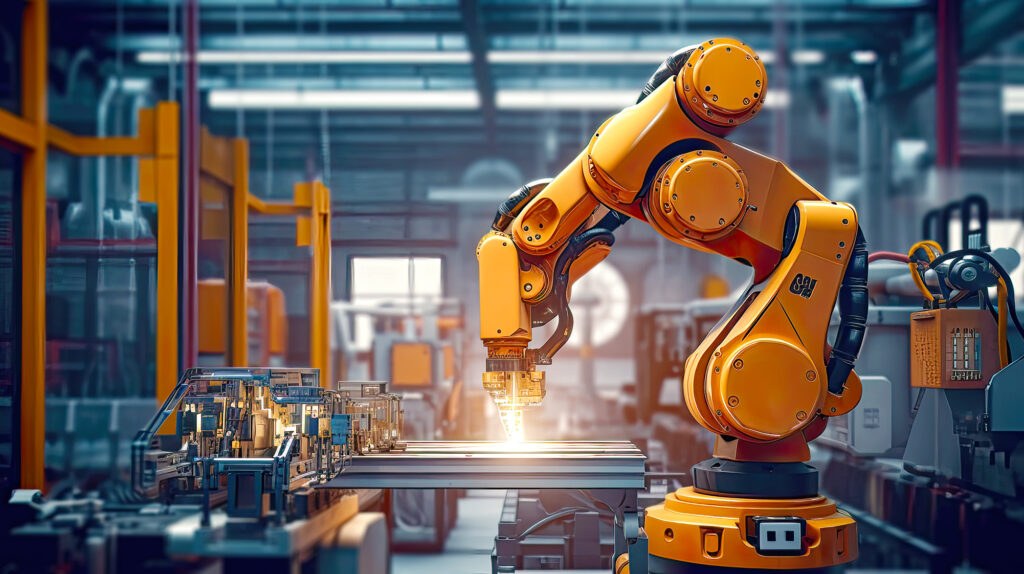

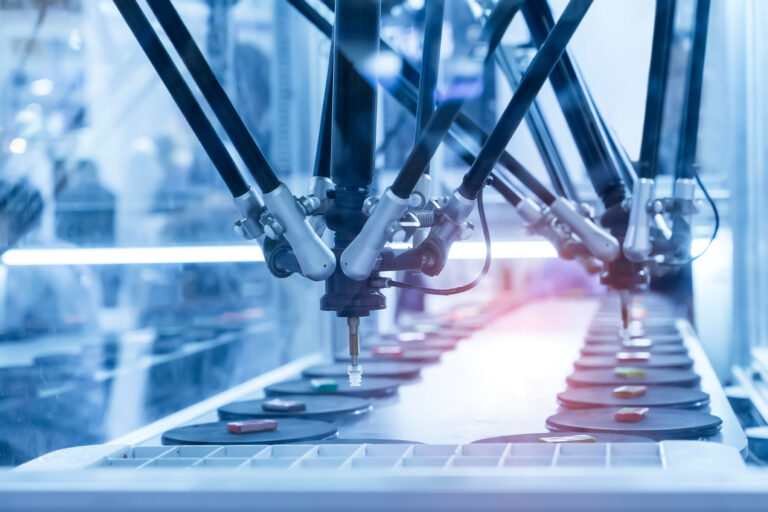

Automation is a critical component of maintaining work safety. From increasing storage density by using an Automated Storage and Retrieval System (ASRS) to store heavy items vertically, to deploying robots in hazardous environments, to even reducing repetitive motion injuries, automation enhances efficiency, minimizes risks, and promotes a secure workplace environment.

At MOT, safety remains at the core of our mission as we work towards delivering innovative solutions that transform facilities while ensuring the safest work environment for those who operate in them.

Alex Pool, President

Transforming Safety and Efficiency: Case Study

A few years ago, an entrepreneur from California’s central valley approached me seeking process improvement and automation solutions for his business. His lucrative venture involved recycling carpets salvaged from demolished buildings and selling them to manufacturers in China. However, his existing process involved a hazardous task where operators had to manually feed sheets of carpet into a machine that would separate the material from the backing. Due to the durable craftsmanship of the carpets, the machine was the only reliable and consistent method for separation. It posed significant risk to the operators as spinning exposed blades and rollers could catch their fingers within seconds, creating an immediate safety threat.

As we interviewed the client and started developing a custom safety-first process, we learned that he was having quality issues due to material misidentification. During discovery, my team watched the process in action (unloading, sorting, staging, and feeding) and quickly realized his teams were handling the material multiple times due to inefficient storage and handling procedures.

The engineering teammates (who now work for Masked Owl Technologies) leveraged their observations to develop a comprehensive automated solution for the client’s needs. With this solution, the unloading process was followed by material feeding into the system, where it underwent identification, sorting, storage, and batch processing to eliminate cross-contamination. This approach significantly reduced headcount from 10 operators per shift to just 2. By involving operators solely in the safe unloading process, they were kept at a safe distance from potential hazards such as spinning blades and pinch points.

Custom trays were used to hold the carpet, allowing it to be conveyed over standard roller conveyors and staged in an ASRS to allow material types and colors to run together. Material type and color were identified using an automatic version of the manual instrument the company was already using. Once the team solved those challenges, the rest of the system became a standard material handling, sortation, and feed system.