December 6, 2024

~:

5 Mins

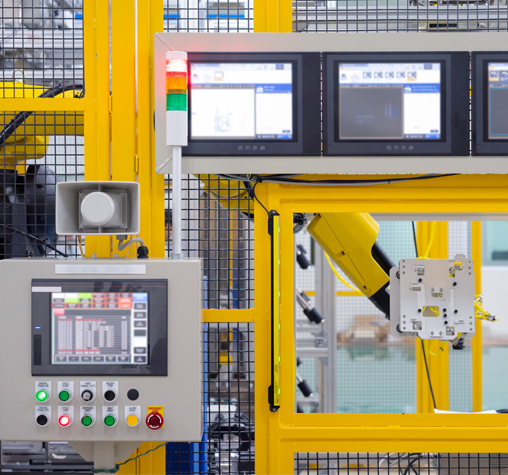

A manufacturer with multiple production sites sought to improve operator efficiency through better use of HMI graphics and alarms. Their existing system used complex, visually cluttered graphics that slowed down operator response times. The company aimed to reduce confusion, streamline processes, and improve focus on critical system components, ensuring faster response times and consistent operations.

The Challenge

The project required a deep understanding of the ISA 101 and ISA 18.2 standards, which guide HMI design and alarm management. Implementing the intent behind these standards was particularly difficult for the Level 1 overview screens due to the size limitation of the 12-inch displays. Balancing minimalism with conveying all the necessary information at the overview level, while still maintaining clarity and usability, proved challenging, especially for such a large system.

The Solution

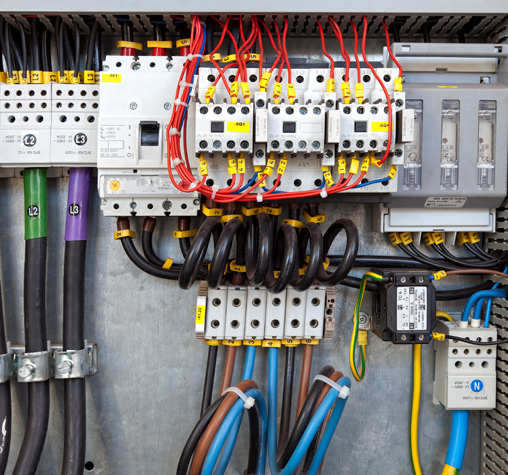

The team revamped the HMI screens to align with ISA 101 standards, moving away from the visually distracting graphics and color schemes to a cleaner, grayscale design. The new graphics emphasized minimal color, reserving bright colors for alarms and warnings only. The screens were designed to provide clear overviews while supporting specific operational needs at various levels; Level 1 was designed for a process overview, while Level 2 focused on area overview. At the same time, the alarm system was reevaluated using the ISA 18.2 standards, focusing on minimizing unnecessary alarms. Only alarms requiring direct operator action were kept, reducing distractions and enabling operators to prioritize significant system alerts.

The Impact

Initially, the updated graphics and alarm systems faced resistance from operators accustomed to the old system. However, after several months of use, the customer reported significant improvements in operator focus and efficiency. The simplified, streamlined graphics made it easier to identify and address critical issues. The reduction in nuisance alarms led to fewer unnecessary interventions, helping operators trust the system more and react only when necessary. Overall, the customer expressed satisfaction with the enhanced HMI and its positive impact on operations.

Relevant Case Studies

Clear Filters

INSIGHTS

Distributed HMI Systems and Remote Automation for Efficient, Safe Manufacturing

INSIGHTS

Leveraging Intrinsically Safe I/O Systems to Ensure Plant Safety

INSIGHTS

Minimizing Downtime While Ensuring Worker Protection in Hazardous Environments